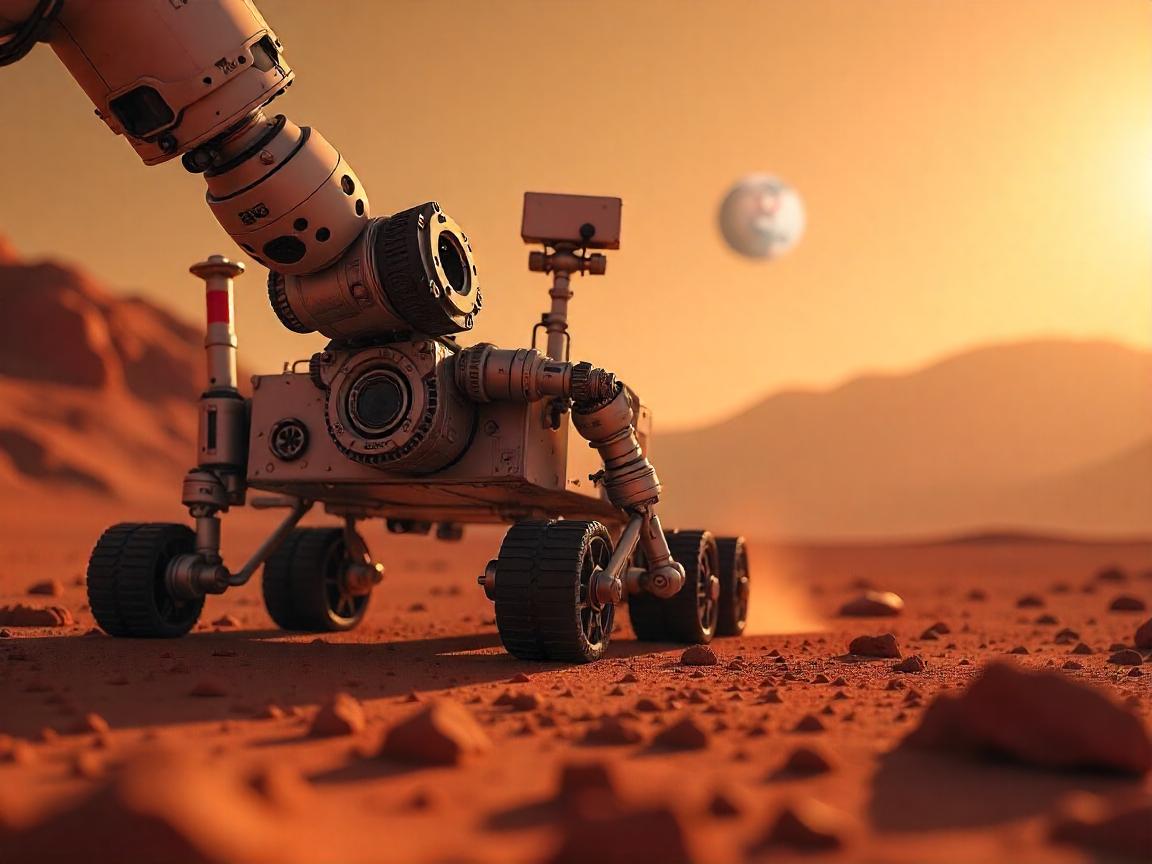

Space exploration often reminds us of large rockets, daring astronauts and major discoveries from outer space. Yet what makes this possible are tiny robotic items, smaller than your palm, that are responsible for entire space mission outcomes. A particularly calm hero? Precision motors is what the brand is known for. These little machines aren’t only working parts; they’re also helping to make history in space, mainly on Mars.

It’s not Extra Power That We Need at Mars: We Need Better Precision

There are no second chances in space. Mars temperatures can be as low as -80°C, dirt gets everywhere and delays in communication prevent operators from controlling things in real time. Therefore, mechanics must make every grip, twist and probe correct the very first time. That’s why Swiss motors from maxon play an important role. They’re designed for extremely high accuracy, allowing bent robotic arms to carefully manage small soil samples just as a human would handle a single snowflake.

For example, many of the brushless DC motors and gearheads from maxon are packed inside the Perseverance rover sent out by NASA. The sensors on the rover are set up so that, after installation, they can work flawlessly for years on Mars. In 2021, the Perseverance rover began gathering samples intended for return to Earth by 2033, entirely through the use of precise robotic systems. If there is a mistake in the handing of sensitive materials, it could undo decades of careful planning, Space.com states.

Inside the Red Planet’s Robotic Toolkit

Perseverance isn’t only used to take photos during its journey. The facility is a fully independent lab with a robotic arm, coring drill and a tube carousel for samples. To use these systems well, you need to move your body gently yet firmly and at a controlled speed, yet quickly. In that area, Swiss robotics are truly impressive. This means that the Sample Caching System counts on high-torque maxon drives to carry soil cores into a sterilized container. With the use of programmed feedback loops and AI such tasks are orchestrated, all without human assistance.

Rosalind Franklin rover from ESA, now slated for launch in 2028 because of shifts in politics, is also set to use Swiss motors. Instead of digging just one meter as Perseverance did, Rosalind Franklin goes down two meters, more than any previous rover, so its drill has to work against greater resistance, more torque shifts and farther differences in terrain. The robot’s real-time adaptability is made possible by the servo systems which are tested in Mars-related vacuum environments.

Seeing the World from a Clean Room

To fix a problem on Mars, says Dr. Andreas Wenger, “You can’t just get a file or unzip something.” When something goes wrong with a motor and your out, that’s the end of the ride. Either the technology functions properly or it becomes a problem.”

Such important work in space robotics has created a culture without room for errors. It takes years for engineers to simulate dust storms, extreme cold and exposure to changes in temperature in special labs. The All Spacecraft are rigorously sterilized to make sure contamination from Earth isn’t possible. Even the presence of small amounts of biology in space can disrupt the search for life and one single contaminant could ruin an entire mission, an article by NASA Jet Propulsion Laboratory revealed.

It’s notable that much of the advanced technology for space comes from companies with roots in the watchmaking industry. The same devotion to precision in watchmaking now brings satellites safely to space by using gears previously meant for timekeeping.

What We Learn from a Land That Won’t Forgive

Let’s examine how this works with a real account. In 2018, the mole, the heat probe on the InSight lander, became stuck underground on Mars. Unlike what Perseverance’s system had, the mole hammered instead of relying on modern robotics. The tool had to be scrapped following two years of problems, illustrating that accurate engineering outperforms raw effort in space. It is clear why future missions using robots are choosing to depend on fluid movements over strong and sudden reactions.

Important points learned from missions like Perseverance are:

- Everything must be programmed in advance and made safe to work in any environment.

- Samples from the soil should be free from contamination, to be used on future missions.

- Motors need to run for thousands of hours while still needing little or no maintenance.

- Machines in space are threatened every day by radiation, vibration and extreme cold.

Conclusion: Silent Sentinels on Mars

While we plan trips to the Moon, Europa or set goals for manned missions to Mars, our strongest backup won’t appear in every news story. They’ll do all the work carefully in silence, leaving the world’s future under alien skies. The name Swiss robotics is now among the most respected in that area.

The lesson? You don’t win space through brute power, you win it through precision. Since a single mistake with a giant satellite can ruin a huge mission, it’s the minor parts—carefully made and precisely built—that help guide future discoveries.

The next time you see a picture of Mars, simply think of those Swiss motors in that red dust, as they made tiny parts of history.